Revolutionizing the Lighting Industry with Energy-Efficient Manufacturing

The lighting industry is undergoing a transformation with the adoption of energy-efficient manufacturing techniques. As global energy consumption continues to rise, manufacturers are increasingly prioritizing energy-efficient manufacturing to reduce their carbon footprint and operational costs. Imagine a world where factories glow with efficiency, much like a perfectly optimized LED bulb—bright, effective, and waste-free! Implementing energy-efficient manufacturing not only aligns with environmental goals but also enhances overall productivity and cost-effectiveness. In this article, we will explore key strategies, technological advancements, and best practices that are driving energy-efficient manufacturing in lighting production.

Innovative Approaches to Energy-Efficient Manufacturing

1. Lean Manufacturing Techniques

Lean manufacturing principles play a crucial role in minimizing waste and optimizing energy-efficient manufacturing processes in lighting production. Think of it as decluttering your workspace—except on a massive, industrial scale! By streamlining processes, manufacturers can:

- Reduce excess material consumption

- Enhance production speed and efficiency

- Minimize energy wastage in machining and assembly

2. Advanced Automation and Smart Manufacturing

The integration of automation and smart technologies significantly improves energy-efficient manufacturing. Key advancements include:

- IoT-Enabled Systems: Smart sensors monitor energy consumption in real time, allowing for immediate adjustments to optimize efficiency—like having a fitness tracker for your factory!

- Robotics: Automated assembly lines reduce human error and improve precision, leading to lower energy consumption. Imagine robots assembling light fixtures with the precision of a master craftsman but at lightning speed.

- Predictive Maintenance: AI-driven analytics help identify potential equipment failures, reducing downtime and energy losses—think of it as giving machines their own personal doctor!

3. Sustainable Materials and Eco-Friendly Practices

Sourcing sustainable materials is a fundamental aspect of energy-efficient manufacturing. Best practices include:

- Recyclable Components: Using LED housings made from recycled aluminum or bioplastics—because second chances aren’t just for people!

- Eco-Friendly Coatings: Employing non-toxic coatings to enhance durability and efficiency—because who likes toxic relationships anyway?

- Minimizing Waste: Implementing circular economy principles by reusing and recycling raw materials—turning yesterday’s scraps into tomorrow’s innovation!

4. Energy-Efficient Production Facilities

Modern lighting manufacturers are adopting various strategies to improve energy-efficient manufacturing in their production facilities, such as:

- Renewable Energy Integration: Utilizing solar and wind energy to power factories—think of it as Mother Nature picking up the electricity bill!

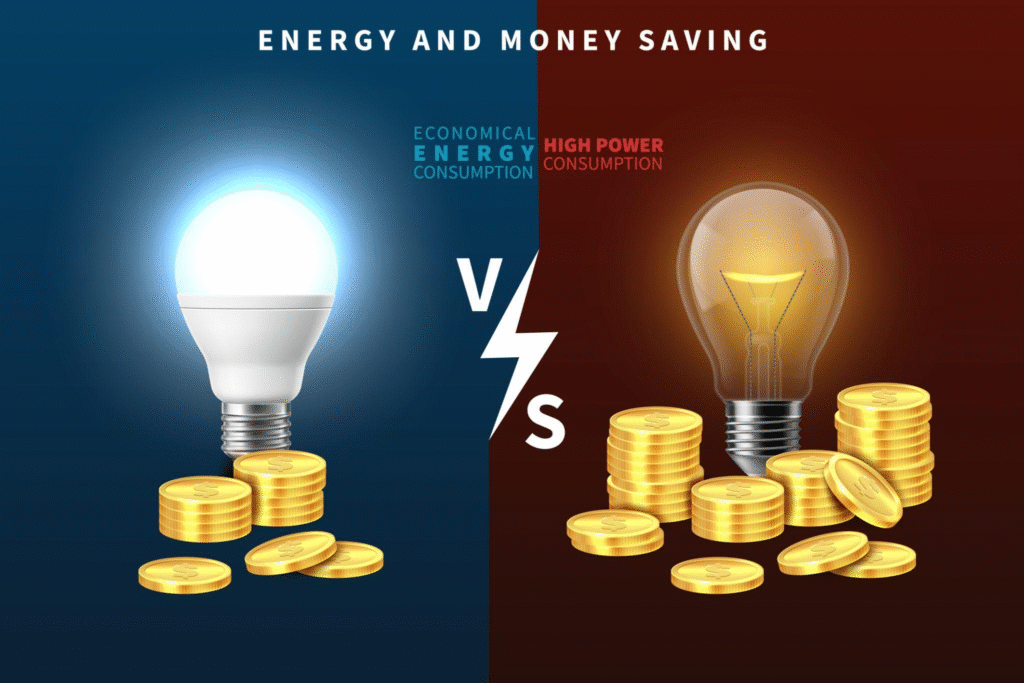

- LED Lighting in Facilities: Replacing traditional lighting with high-efficiency LED fixtures to reduce energy consumption—because what kind of lighting company would use inefficient bulbs?

- HVAC Optimization: Implementing smart climate control systems to minimize energy waste in heating, ventilation, and cooling—keeping factories comfortable without the energy binge.

5. Sustainable Supply Chain Management

A comprehensive approach to energy-efficient manufacturing extends beyond production lines to the entire supply chain. Key strategies include:

- Optimized Logistics: Implementing route optimization to reduce fuel consumption—because taking the scenic route isn’t always the best option!

- Sustainable Packaging: Using biodegradable or recyclable packaging materials—because even packaging deserves a second life.

- Supplier Collaboration: Partnering with suppliers who adhere to sustainable practices—because teamwork makes the green dream work!

Benefits of Energy-Efficient Manufacturing in the Lighting Industry

1. Reduced Operational Costs

Implementing energy-efficient manufacturing techniques leads to significant cost savings by reducing energy consumption and material waste. More money saved = more investment in innovation!

2. Lower Environmental Impact

Eco-friendly manufacturing practices contribute to reduced carbon emissions, promoting sustainability in the industry. It’s like giving the planet a much-needed breather!

3. Improved Product Quality

Advanced technologies and precision engineering result in higher-quality lighting products with longer lifespans and better performance—because nobody likes a flickering bulb!

4. Regulatory Compliance

Energy-efficient manufacturing practices help manufacturers comply with international environmental regulations and sustainability standards. No one likes red tape, but this is one way to stay ahead of it!

5. Enhanced Brand Reputation

Companies adopting green manufacturing practices appeal to eco-conscious consumers and gain a competitive edge in the market. Who wouldn’t want to be known as the Tesla of lighting?

Frequently Asked Questions (FAQ)

1. What is energy-efficient manufacturing in the lighting industry?

Energy-efficient manufacturing involves using sustainable materials, automation, and optimized processes to reduce energy consumption and waste in lighting production.

2. How does automation contribute to energy efficiency?

Automation enhances precision, reduces errors, and optimizes energy use by employing smart sensors, robotics, and AI-driven systems in manufacturing.

3. What are the key benefits of adopting energy-efficient manufacturing techniques?

Benefits include lower operational costs, reduced environmental impact, improved product quality, regulatory compliance, and enhanced brand reputation.

4. What role does renewable energy play in energy-efficient manufacturing?

Renewable energy sources such as solar and wind power help reduce reliance on non-renewable energy, lowering overall carbon emissions in the manufacturing process.

5. How can lighting manufacturers implement sustainable supply chain practices?

Manufacturers can optimize logistics, use sustainable packaging, and collaborate with eco-friendly suppliers to reduce their overall environmental footprint.

Join the Future of Energy-Efficient Lighting Manufacturing

The transition to energy-efficient manufacturing is not just an industry trend but a necessity for sustainable growth. By adopting these innovative techniques, lighting manufacturers can significantly reduce their environmental impact while boosting operational efficiency. Don’t get left in the dark—embrace the future of energy-efficient manufacturing today!