High bay lighting is one of the most energy-intensive lighting applications in industrial and commercial facilities. Warehouses, factories, logistics centers, and large retail spaces depend on high bay fixtures for long operating hours and wide-area illumination. Because of this heavy usage, even small inefficiencies result in high electricity costs. A detailed high bay energy comparison between traditional high bay lighting and LED high bay solutions is essential for making cost-effective and sustainable decisions.

This article provides an in-depth high bay energy comparison, focusing on energy consumption, performance stability, operational behavior, and long-term efficiency.

1. Overview of High Bay Lighting Applications

High bay luminaires are designed for spaces with ceiling heights typically above 6 meters. These environments require powerful fixtures capable of delivering high lumen output with uniform distribution.

Common applications include:

- Industrial warehouses

- Manufacturing plants

- Distribution and logistics centers

- Aircraft hangars

- Large retail and wholesale stores

- Sports halls and indoor arenas

Because lighting systems in these spaces often operate between 10 and 24 hours per day, high bay energy comparison becomes a critical part of facility energy management.

2. Traditional High Bay Lighting Technologies

Before LED adoption, most high bay installations relied on conventional lighting technologies.

Common traditional high bay types:

- Metal Halide (MH)

- High-Pressure Sodium (HPS)

- Fluorescent T5 and T8 High Bay systems

While these technologies provided sufficient brightness, they suffer from high power consumption and declining efficiency over time, which negatively impacts any high bay energy comparison.

3. Energy Consumption of Traditional High Bay Systems

Traditional high bay fixtures require high wattage to meet illumination requirements.

Typical power ratings:

- Metal Halide: 250W to 1000W

- High-Pressure Sodium: 250W to 600W

- Fluorescent High Bay: 216W to 432W

In a real-world high bay energy comparison, these systems often operate continuously at full power, regardless of occupancy or daylight availability. This fixed-output operation leads to significant energy waste.

4. LED High Bay Lighting Technology

LED high bay luminaires use solid-state lighting technology optimized for high efficiency and long operational life. They provide high lumen output with much lower electrical input.

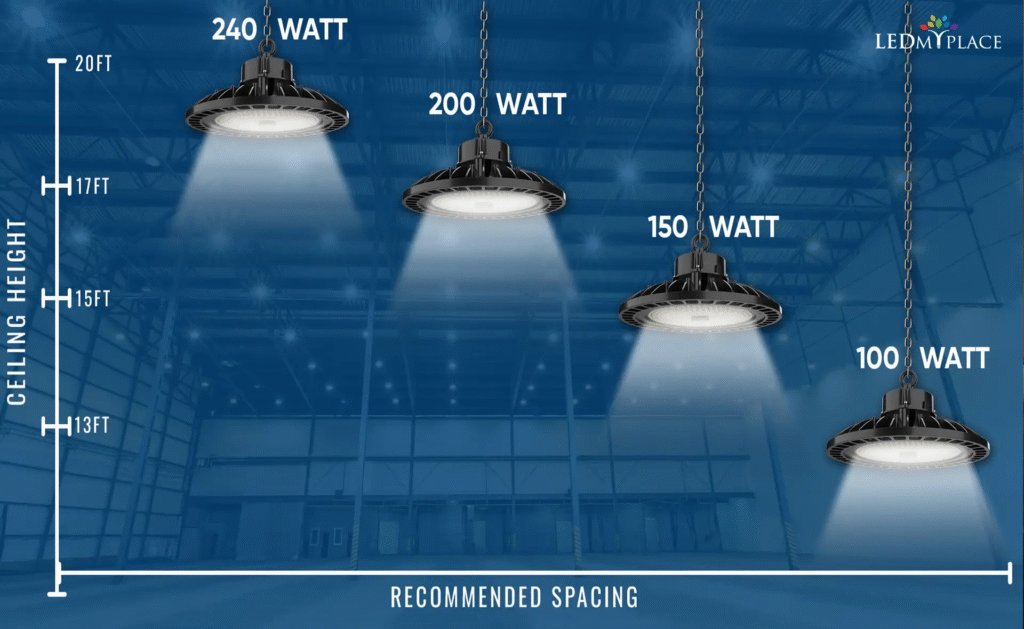

Typical LED high bay power ranges:

- LED High Bay: 100W to 240W

Despite lower wattage, LED fixtures often outperform traditional systems in brightness and uniformity. This performance advantage strongly influences high bay energy comparison results.

5. High Bay Energy Comparison: Power Efficiency

When performing a direct high bay energy comparison, LED technology consistently demonstrates superior efficiency.

Key efficiency differences:

- LEDs consume 40%–70% less power

- Instant full brightness without warm-up time

- Stable output throughout operation

- Compatibility with dimming and smart controls

This efficiency gap is the core reason why LED solutions dominate modern high bay energy comparison studies.

6. Annual Energy Consumption Analysis

High bay lighting operates for extended hours, which amplifies energy differences.

Example high bay energy comparison scenario:

- 400W Metal Halide fixture

- 150W LED High Bay fixture

- Operating 12 hours per day

Annual impact:

- Traditional system consumes over twice the energy

- LED system saves more than 2,000 kWh per fixture annually

Across large facilities, this high bay energy comparison translates into massive cost savings.

7. Heat Generation and Indirect Energy Loss

Traditional high bay systems convert a significant portion of electrical energy into heat rather than usable light. This excess heat increases cooling demands in indoor facilities.

LED high bay fixtures produce significantly less heat. This indirect benefit improves overall building efficiency and strengthens the results of any high-bay energy comparison, especially in climate-controlled spaces.

8. Performance Degradation and Maintenance Impact

Traditional lighting systems suffer from rapid lumen depreciation and frequent component failures.

Common issues include:

- Light output drops over time

- Lamps and ballasts require regular replacement

- Maintenance downtime disrupts operations

As light levels decrease, facilities often compensate by increasing lighting quantity or wattage, worsening high-bay energy comparison outcomes.

LED high bays maintain stable output for most of their lifespan, improving long-term efficiency.

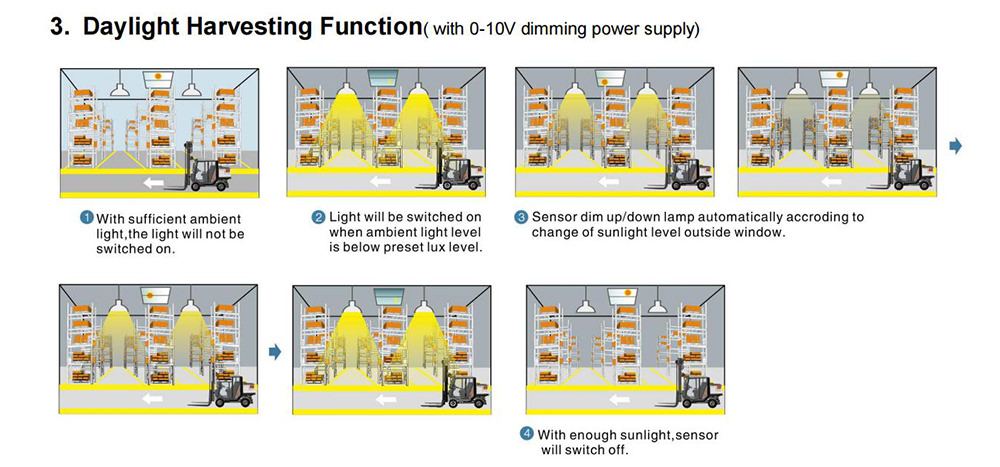

9. Control Capability and Smart Energy Management

Another major factor in high bay energy comparison is control compatibility.

Traditional systems:

- Limited dimming capability

- Poor integration with sensors

- Manual operation

LED high bay systems support:

- Occupancy sensors

- Daylight harvesting

- Scheduled dimming

- Smart lighting platforms

These control options further reduce energy consumption and enhance high bay energy comparison results.

10. Environmental and Sustainability Considerations

Lower energy consumption directly reduces carbon emissions. Replacing traditional high bay fixtures with LED alternatives significantly improves sustainability performance.

From an environmental perspective, high bay energy comparison clearly favors LED solutions due to:

- Reduced power demand

- Longer service life

- Lower waste generation

11. Total Cost of Ownership in High Bay Energy Comparison

A complete high bay energy comparison must consider more than initial fixture cost.

Total cost factors include:

- Electricity consumption

- Maintenance and replacement costs

- Labor and downtime

- System lifespan

Although LED high bays may require higher upfront investment, their lower operating and maintenance costs result in a lower total cost of ownership.

12. Practical Decision-Making Based on High Bay Energy Comparison

Facilities evaluating lighting upgrades should rely on data-driven high bay energy comparison rather than initial cost alone.

Key decision criteria:

- Operating hours

- Energy tariffs

- Ceiling height and layout

- Maintenance accessibility

- Control system requirements

LED high bay solutions consistently deliver superior results across these factors.

Falcon LED High Bay Solutions

Falcon offers advanced LED High Bay fixtures designed to deliver superior high-bay energy comparison results.

Key benefits:

- Up to 70% energy savings

- High and stable lumen output

- Advanced thermal management

- 50,000-hour lifespan

- Smart control compatibility

Falcon LED High Bay solutions are ideal for warehouses, factories, and large commercial spaces seeking long-term efficiency.

Conclusion

Energy consumption is one of the most critical variables in high bay lighting decisions. A detailed high-Bay energy comparison between traditional and LED high bay systems clearly demonstrates that LED technology offers substantial advantages in efficiency, stability, and long-term cost reduction.

For facilities operating high bay lighting for extended hours, upgrading to LED high bay fixtures is not simply a modernization step—it is a strategic investment that delivers measurable energy savings, operational efficiency, and sustainability benefits.

Sources:

- U.S. Department of Energy – Office of Energy Efficiency & Renewable Energy

- International Energy Agency (IEA)

Suggested Topics :